How I Used Project Management Techniques to Improve My Golf Game

I spent many years managing complex business operations and digital transformation projects at work. I was the guy who could optimize a workflow in my sleep, achieved a 30% reduction in manual task loads through process improvements, and even earned back-to-back President’s Awards for operational excellence.

But my golf game? That was complete chaos.

Then it hit me during a particularly frustrating round: Why wasn’t I applying the same discipline that made me successful in business operations to my golf game? I had my Lean Six Sigma Green Belt certification hanging on the wall, yet I was approaching golf like a complete rookie.

That realization changed everything.

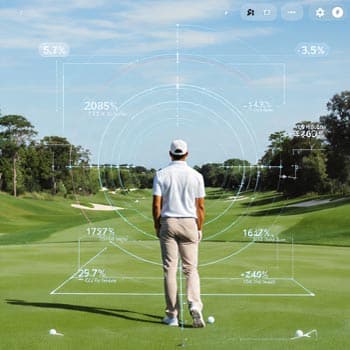

Six months later, I’d dropped nine strokes off my handicap and launched Golf Course Intel – a company dedicated to bringing data analytics and strategic planning to golfers everywhere. Here’s exactly how project management techniques transformed me from a frustrated weekend hacker into a strategic player with a plan.

The Awakening

There I was, standing on the 18th tee, down two sleeves of golf balls and completely demoralized. I realized my approach to golf was completely reactive – I practiced whatever felt fun that day. I bought clubs based on website reviews, not data. And I had no measurable goals, no timeline, and zero accountability.

For someone who spent years designing dashboards and KPI trackers for enterprise-level projects, this was embarrassing.

I decided to treat my golf improvement like a business initiative. And just like any successful project, it needed a plan. So I made one:

15 Project Management Strategies That Transformed My Golf

1. I Defined Clear, Measurable Objectives (SMART Goals)

I stopped saying “get better” and started setting SMART goals (Specific, Measurable, Achievable, Relevant, and Time-bound) – the same framework I used at work for digital transformation projects.

My specific targets: reduce my handicap by 6 points within six months, achieve 50% fairway accuracy, and eliminate three-putts from within 15 feet.

2. I Conducted a Skills Gap Analysis

Just like assessing team capabilities before a major system integration, I honestly evaluated my golf strengths and weaknesses. Turns out, my driver was fine – but my short game was costing me six strokes per round. This changed everything about how I allocated practice time.

3. I Created a Practice Roadmap with Milestones

I built a six-month roadmap using the same methodology I’d used for enterprise software rollouts. Month one: establish baseline metrics. Month two: improve chipping accuracy to 70%. Each milestone was specific, measurable, and time-bound.

4. I Applied the 80/20 Rule (Pareto Principle)

Data showed that 80% of my lost strokes came from 20% of my game: shots within 100 yards and putting. I reallocated 70% of my practice time to these areas immediately – the same prioritization approach I’d used in operational excellence initiatives.

5. I Implemented Lean Six Sigma Process Improvement

As a certified Six Sigma Green Belt, my eyes are trained to spot waste and variance in a process. In golf, “waste” (Muda) is any shot that doesn’t advance you toward the hole or incurs a penalty.

- Process Mapping: I mapped the “value stream” of a par 4. The goal isn’t the longest drive; it’s the most efficient path to the cup.

- Reducing Variation: Consistency is key. I stopped changing my swing thought every hole. I committed to one process, knowing that in Operations, standardized SOPs lead to predictable results.

6. I Practiced with Purpose and Metrics

Every practice session had objectives, success criteria, and data collection – exactly how I approached workflow automation projects. I used Golf Pad Tags Smart Sensors to track every shot, then analyzed patterns in spreadsheets, just like I’d done with PowerBI dashboards at work.

This post contains affiliate links. If you use these links to buy something, I may earn a commission at no extra cost to you. Thanks for your support!

7. I Chose Right-Size Equipment for my Current Capabilities

Instead of aspirational clubs, I chose equipment for my actual game – the same pragmatic approach I took with technology adoption. For me, switching to TaylorMade Tour Response Golf Balls improved my distance control because they matched my swing speed, not my ego.

8. I Developed a Risk Management Framework

I created a risk matrix for every shot on the course – high risk/high reward versus low risk/consistent results. This was straight from the project management playbook. Conservative strategy dropped my blow-up holes by 60%, similar to how risk mitigation improved project outcomes in my corporate work.

9. I Optimized Pace of Play Through Time Management

I analyzed how long each part of my routine took and eliminated time-wasters – the same continuous improvement mindset that reduced manual task loads by 30% in my operations role. To help, I started using a Rangefinder for faster club selection, keeping the group on schedule.

10. I Built Etiquette into Standard Operating Procedures

Good etiquette is good project management – it keeps things moving smoothly and builds team morale. I standardized my course behavior: repair divots immediately, stay ready, read putts while others play. SOPs work on the course just like they do in business operations.

11. I Created a Continuous Improvement Loop

After every round, I held a “retrospective” – the same post-project review process I’d facilitated numerous times. What went well, and what didn’t? What will I change? I logged insights using the same tracking methods I’d used at work for system optimization.

12. I Managed Resources and Budget Strategically

In my career, I specialize in vendor management and rigorous bid analysis. I realized I wasn’t applying this scrutiny to my own equipment – I was carrying clubs that didn’t “win the bid” for my bag.

I conducted a “bid analysis” on my 3-iron. It had a high failure rate and low ROI. I “terminated the contract” and replaced it with a hybrid that offered better compliance with my swing speed.

I stopped impulse-buying gear and created a resource allocation plan. Where would investments yield the highest ROI? That $500 driver won’t help as much as a few lessons on fixing my short game – this was basic vendor management and bid analysis applied to golf.

13. I Performed Root Cause Analysis on Bad Shots

Instead of “I suck,” I asked “Why?” – the fundamental Six Sigma question. Poor contact? Alignment issue? Grip pressure? This root cause methodology led to targeted fixes, not band-aid solutions, just like in process improvement projects.

14. I Built a Performance Dashboard

I created a simple dashboard tracking key metrics: fairways hit, greens in regulation, putts per round, and scrambling percentage. Visual progress kept me motivated through plateaus – the same KPI tracking approach that drove accountability in enterprise projects.

15. I Executed Daily Stand-Ups (Mental Game Check-Ins)

Before each round, I do a five-minute mental “stand-up”: review my game plan, confirm my process goals (not outcome goals), and set my intention. It’s the same alignment practice I used with cross-functional teams before major initiatives.

The Results Speak for Themselves

Seven months in, I’m playing the best golf of my life. My handicap has dropped nine points. I’m accepting the challenges of playing tougher golf courses. More importantly, golf is fun again because I have a plan and I’m seeing measurable progress.

This success led me to found Golf Course Intel in 2025, where I’m now applying these same methodologies – plus advanced data analytics and AI-powered insights – to help golfers at every level improve strategically.

The beauty of this approach? It works for any skill level. Whether you’re a 25 handicap or scratch golfer, project management principles provide structure, accountability, and a clear path forward.

Your Next Step

Want to apply these strategies to your game but you’re not sure where to start? At Golf Course Intel, we’ve created comprehensive Golf Course Intel Strategy Guides that use this methodology to make it personal for you.

The guides will help you:

- Identify personalized drills and stretches based on your specific weaknesses (Fairway Fundamentals)

- Find the perfect golf ball and clubs for your swing characteristics and course conditions (Fairway Fundamentals MAX)

- Develop a hole-by-hole, shot-by-shot strategy for conquering any course in the world (available in the Elite Performance tier)

You don’t need to be a tour pro to think like one. You just need a better project plan.

Are you ready to officially launch “Project Lower Handicap“?

0 Comments